I did a dumb thing but it turned out OK. When I took the Cayman out of winter storage this spring and warmed it up for the first time in a while, I smelled coolant, although none leaked to the ground. I have seen water pump seals do this before. On most older cars the water pump has a simple bushing that runs in coolant so a small seep that quits is not necessarily a big deal. My F250 would do this on severe cold weather but never had a pump failure. However, the Cayman water pump is not like that. It has a sealed roller bearing instead, which is far better and should last for life. However, if you get coolant seeping through the bearing, the bearing will die pretty fast. The grease will get washed out, the bearing will run dry, and fail. Well, that is what happened to me. I had noticed a growling noise from the engine when I started it that morning. My first thought was far worse than a water pump. I feared my IMS bearing was going out. After recalling that I did see dry evidence of coolant from the water pump I sorta convinced myself it could just be some coolant on the belt, which can make all sorts of weird noises. Honestly I was not that convinced, I was just lazy and in a hurry to meet with some friends.

On my way back from breakfast where I was meeting with friends I heard a pop and immediately my steering assist was gone and the charging system warning came ON. Right away I knew I had lost the belt. I carefully drove the rest of the way home, accelerating moderately up to speed, shutting OFF the engine, and coasting between lights. By the time I got home the coolant temp was a bit over 200F based on the gauge. Still safe but I would not want to get it too much hotter. With no belt, the coolant does not circulate. You can't go very far like that. In the video below you can hear the pop right at the beginning.

It is not real loud and I did have the stereo going. I quickly turned OFF the AC and opened the windows too.Once I was home, I removed the panel behind the seats to expose the front of the engine where the belt and water pump are. I saw the slack belt but upon further inspection I found the water pump shaft had completely sheared off and the pulley was just laying there.

Glad to see it was just a water pump, I quickly ordered parts through the local dealers online website.

Mid-engine cars have a much trickier cooling system since the engine is in the middle, and the radiators are in the front fenders ahead of the wheels. This makes it an air pocket nightmare. A vacuum system is needed to pull a vacuum on the cooling system and suck the coolant in. I found this one on Amazon for $39.99.

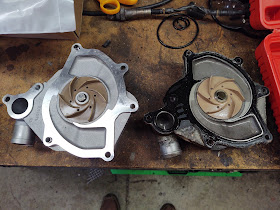

When installing the new pump, make sure the longer bolts are in the correct holes, with the alignment dowels. Here you can see the new and old pumps, both showing the alignment dowels.